SC manufactures

a variety of products, with some able to reach liquid pressures of 65,000 psi

or gas pressures exceeding 17,000 psi:

- Air operated liquid pumps

- Air Boosters and Systems

- Gas Boosters and Systems

- Power Units

- High Pressure Stainless Steel Valves

SC Air Operated

Liquid Pumps

1. L3 and L3C

Series Liquid Pumps

These are more

compact than other liquid pumps available. They are air operated with pressure

capable of exceeding 18,000 psi. Wetted sections are available in stainless

steel and carbon steel. They can be used with de-ionized water, nitrous oxide,

and carbon dioxide. Remote pilot and hand pump options are available.

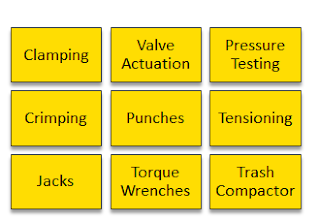

Common applications:

General

Information:

Air

Drive

Require no electrical power. Powered by

pressurized air, nitrogen vapor, or natural gas. The air drive psi supplied is

translated to output pressure using the pressure ratio. If the pressure ratio

of the pump is 20:1 and air drive pressure supplied is 50 psi, this means the

output pressure is approximately 1,000 psi. A hand pump attachment option is

available for precise pressure control or great for applications where shop air

is not available.

L3 & L3C ratios available: 20:1, 31:1,

40:1, 55:1, 79:1, 123:1, 133:1, 213:1

- Starting air drive pressure: < 15 psi

- Max air drive pressure: 125 psi (intermittent duty)

- Max output pressure: 24,375 psi at 125 drive psi, 1.0 gpm flow rate

Operation

These pumps operate using the principle of

differential areas. A small diameter hydraulic plunger is driven by an air

piston and provides a pressure ratio that determines the maximum output

pressure.

Cycle

When air is first supplied to the pump, the

pump will cycle at maximum speed with maximum flow. It will continue to cycle

automatically as the pressure increases. Only slight drops in outlet pressure

or increase in air drive pressure will occur each cycle, thanks to very low

frictional resistance.

Equilibrium

When the air drive force and output

pressure are equal, the pump stops automatically. The pump will maintain

pressure with zero energy consumption.

Media

- Plain water

- All hydraulic fluids

- Distilled and di-ionized water

- Solvents

- Mild chemicals

- Liquified CO2

Features

- 316 Stainless Steel wetted hydraulic construction

- Lightweight (6 lbs)

- 3.5-inch x 7-inch body includes inlet and exhaust muffler

- Hand pump attachment option

2. 10-4 Series Liquid Pumps

These are designed for high output

capacity, easy maintenance, and wide ranges of operating pressures and output

capacities.

Common applications:

Great for applications requiring extreme intermittent pressure, such as in water blasting.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen vapor, or natural gas. The air

drive psi supplied is translated to output pressure using the pressure ratio. If the pressure ratio of the

pump is 30:1 and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 1,500 psi.

10-4 Series ratios available: 5:1, 10:1, 15:1, 30:1, 35:1, 55:1, 100:1, 140:1, 220:1, 300:1

3. 10-5 & D5 Series Liquid Pumps

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen vapor, or natural gas. The air

drive psi supplied is translated to output pressure using the pressure ratio. If the pressure ratio of the

pump is 30:1 and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 1,500 psi.

10-4 Series ratios available: 5:1, 10:1, 15:1, 30:1, 35:1, 55:1, 100:1, 140:1, 220:1, 300:1

- Starting air drive pressure: < 10 psi

- Max air drive pressure: 100 psi

- Max output pressure: 29,500 psig at 100 drive psi

- Volume Per Stroke: 0.047 – 2.59 in3

Modifications

10-4 Series has one modification option available: model “A”. These use dual seals in the hydraulic assembly with a bleed-off between the seals to the atmosphere. This makes it easier to identify hydraulic seal leakage by providing a visual indication. One application for this may be where contamination of the air motor from the hydraulic fluid being pumped is undesirable.

These pumps are similar to the 10-4. They may be mounted in any position, but vertical is preferred. A drain cock should be used to drain off any liquid that may accumulate in the pilot valve air chamber if mounted in another position. The D5 Series uses dry lubricant, so it does not require air lubrication. The 10-5 Series requires lubricated air.

General

Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen vapor, or natural gas. The air drive psi supplied is translated to output pressure using the pressure ratio. If the pressure ratio of the pump is 30:1 and air drive pressure supplied is 50 psi, this means the output pressure is approximately 1,500 psi.

10-5 & D5 Series ratios available: 5:1, 10:1, 12:1, 20:1, 25:1, 30:1, 35:1, 55:1, 70:1, 85:1, 105:1,140:1, 195:1, 280:1, 440:1, 555:1

1. Starting air drive pressure: < 10 psi

2. Max air drive pressure: 100 psi

3. Max output pressure: 55,000 psig at 100 drive psi. Intermittent duty above 30,000 psi.

4. Volume Per Stroke: 0.048 – 5.54 in3

Modifications

Six modification options are available.

Model “A” uses dual seals in the hydraulic assembly with a bleed-off

between the seals to the atmosphere. This makes it easier to identify hydraulic

seal leakage by providing a visual indication. One application for this may be

where contamination of the air motor from the hydraulic fluid being pumped is

undesirable.

Model “B” have a bottom inlet connection for tank top connection or

alternate mounting configuration.

Model “C” uses PTFE chevron packing in the hydraulic assembly. This

provides maximum performance when other packing material is not compatible with

the media or when used in extreme temperatures. Furthermore, the modification

from Model “A” is included with PTFE O-rings.

Model “H” uses special packing in the hydraulic assembly. It

provides greater life expectancy from the hydraulic seals in situations where

hydraulic fluid may by contaminated. Furthermore, the modification from Model

“A” is included with PTFE O-rings.

Model “K” uses a special air piston in the air motor assembly that

decreases the stroke of the pump. This decreases the internal forces and

extends the life of the air motor. Great for applications with rapid pressure

drops, such as in burst testing.

Model “R” uses an isolator attachment that prevents the hydraulic

piston from retracting into the air motor. This eliminates the possibility of

contamination through the piston. It also acts as a heat barrier.

4. 10-6 & D6 Series Liquid Pumps

These pumps are similar to the 10-5. They may be mounted in any

position, but vertical is preferred. A drain cock should be used to drain off

any liquid that may accumulate in the pilot valve air chamber if mounted in

another position. The D6 Series uses dry lubricant, so it does not require air

lubrication. The 10-6 Series requires lubricated air.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 35:1

and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 1,750 psi.

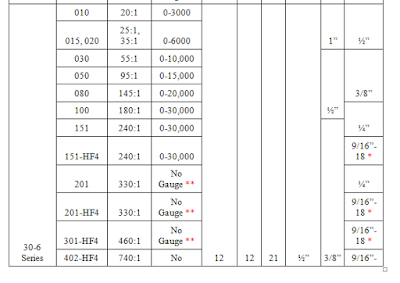

10-6 & D6 Series ratios available: 5:1, 10:1, 20:1, 25:1, 35:1, 55:1,

95:1, 145:1, 180:1, 240:1,

330:1, 460:1, 740:1

330:1, 460:1, 740:1

1. Starting air drive pressure: < 10 psi

2. Max air drive pressure: 100 psi

3. Max output pressure: 65,000 psig at 100 drive psi. Intermittent duty

above 30,000 psi.

4. Volume Per Stroke: 0.123 – 17.7 in3

Modifications

Six modification options are available.

Model “A” uses dual seals in the hydraulic assembly with a bleed-off

between the seals to atmosphere. This makes it easier to identify hydraulic

seal leakage by providing a visual indication. One application for this may be

where contamination of the air motor from the hydraulic fluid being pumped is

undesirable.

Model “B” have a bottom inlet connection for tank top connection or

alternate mounting configuration.

Model “C” uses PTFE chevron packing in the hydraulic assembly. This

provides maximum performance when other packing material is not compatible with

the media or when used in extreme temperatures. Furthermore, the modification

from Model “A” is included with PTFE O-rings.

Model “H” uses special packing in the hydraulic assembly. It

provides greater life expectancy from the hydraulic seals in situations where

hydraulic fluid may by contaminated. Furthermore, the modification from Model

“A” is included with PTFE O-rings.

Model “K” uses a special air piston in the air motor assembly that

decreases the stroke of the pump. This decreases the internal forces and

extends the life of the air motor. Great for applications with rapid pressure

drops, such as in burst testing.

Model “R” uses an isolator attachment that prevents the hydraulic

piston from retracting intothe air motor. This eliminates the possibility of

contamination through the piston. It also acts as a heat barrier.

5. L6 Series High Volume Liquid Pumps

These are great for high flow and high-pressure applications.

Nominal outlet flow ranges from 1 gpm to 2 gpm. They are double acting, single

stage compatible with most fluids and air operated. The parts are wetted

stainless steel.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 40:1

and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 1,500 psi.

1. L6 Series ratios available: 40:1, 69:1, 115:1

2. Max air drive pressure: 100 psig

3. Max output pressure: 11,200 psig at 100 drive psi.

4. Volume Per Stroke: 2.1 – 6.0 in3

Modifications

Two modification options are available. It is required to choose

one.

“Remote Pilot”: Provides a 1/8” NPT female port that can be used to

remotely start and stop the pump. This can be done by connecting an external

air signal to actuate the air cycling valve. This modification is the standard

part number.

“M014” - Counter Port: Provides a 5/8-18-UNF thread port on the air

motor section of the pump which can be used to install a mechanical cycle

counter. This modification does not include the “Remote Pilot” option and

changes part number to include “M014” at the end.

6. L10 Series Double Acting Liquid Pumps

These are even better than the L6 Series for high flow and

high-pressure applications. Nominal outlet flow ranges from 1 gpm to 3.5 gpm.

They are double acting, compatible with most fluids and air operated. The parts

are wetted stainless steel.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen vapor, or natural gas. The Airdrie psi supplied is translated to output pressure using the pressure ratio. See the table for pressure ratings.

* Coned and threaded high-pressure connection for 20 KSI

9/16" O.D. tubing.

** Coned and threaded high-pressure connection for 30 or 60 KSI 9/16" O.D. tubing.

** Coned and threaded high-pressure connection for 30 or 60 KSI 9/16" O.D. tubing.

1. L10 Series ratios available: 33:1, 64:1, 114:1

2. Max air drive pressure: 100 psig

3. Max output pressure: 25,600 psig at 100 drive psi.

4.Volume Per Stroke: 2.15 – 16.84 in3

AB-2, AB-4, and AB-7 Compact Air Boosters

Modifications

Three modification options are available.

“M002” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M014” - Counter Port: Provides a 5/8-18-UNF thread port on the air

motor section of the pump which can be used to install a mechanical cycle

counter.

“M015” – High Pressure Outlet: Provides a 9/16 outer dimension tube

outlet check valve port (13/16-16 UN female thread) rated for 20,000 psi.

7. SC Air Boosters and Systems

AB-2, AB-4, and AB-7 Compact Air Boosters

These have a 4.5” x 5.4” x 7.4” compact design including the mount.

Great for boosting your existing air pressure 2 to 4 times the line pressure up

to 680 psig. Typically used in any low flow, high-pressure application,

including clamping, holding, and leveling.

The AB Series are single-acting, compact units. Inexpensive

alternatives for applications requiring low flow 100-680 psi. Their

portability, economy, light weight, easy installation, and no requirement for

lubrication makes them a great option in OEM application. Remote pilot modification is available.

Common applications:

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. The air drive and supply are the same, so no

extra plumbing is required. If the pressure

ratio of the pump is 7:1 and air drive pressure supplied is 50 psi, this means

the output pressure is approximately 350 psi.

1. AB-2, AB-4, and AB-7 ratios available: 1.7:1, 3.7:1, 7:1

2. Max air drive pressure: 150 psi

3. Max output pressure: 700 psi at 150 drive psi

Modifications

One modification option is available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

8. ABD-2, ABD-2S & ABD-5 Series Air Boosters

The advantage of the ABD Series over the AB

Series is that they have high flow capacity and are double-acting, single

stage. These are great if you have depleted your minimum air supply required

for your system because you may connect the booster to your supply to achieve

your required pressure. The volume from the booster should be enough for most

equipment and the booster can be paralleled for more volume. Skip to “Air Booster Systems” if you require a separate

tank or receiver. Take care that the speed does not exceed 40 cycles per

minute. Reach out to gghyd.com if you need

consultation. Common applications are similar to the AB series above.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 5:1 and

air drive pressure supplied is 50 psi, this means the output pressure is

approximately 250 psi.

1. ABD-2, ABD-2S, and ABD-5 ratios available: 2:1, 5:1

2. Max air drive pressure: 150 psi

3. Max output pressure: 855 psi at 150 drive psi

Modifications

Eight modification options are available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M205” – Cooling Jacket: “B” models have a bottom inlet connection

for convenient tank top installation or alternate mounting configuration.

“M200” – Refrigerant Recovery (2)

“M201” - No Inlet / Outlet Plumbing (2)

“M203” - No Inlet / Outlet Plumbing, Remote Pilot (2)

“M204” - Cooling Jacket (2)

“M206” - Cooling Jacket, No Inlet / Outlet Plumbing (2)

“M207” - Cooling Jacket, No Inlet / Outlet Plumbing, Remote Pilot

(2)

9. AB-2 & AB-4 Air Booster

Systems

These are the most compact sized air

booster systems provided by SC Hydraulics. They are equipped with either an

AB-2 or AB-4 booster along with a 200 cubic inch reservoir, high pressure

gauge, filter/regulator combination with shut-off valve, air drive controls, and

an air pressure gauge. The components

are mounted on a base plate.

These are great in applications where the

booster alone provides too little flow. The reservoir allows the booster to

build up pressure between cycles.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 4:1 and

air drive pressure supplied is 50 psi, this means the output pressure is

approximately 200 psi.

1. AB-2 and AB-4 ratios available: 2:1, 4:1

2. Max air drive pressure: 150 psi

3. Max output pressure: 600 psi at 150 drive psi

4. Dimensions: 18.25” x 12.5” x 6”

5. Weight: approx. 35 lbs.

Modifications

One modification option is available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

10. ABD-2 Air Booster System

This air booster system is made for high

volume applications that may require up to 250 psi air reserve. A 15 gallon

ASME receiver is attached to the double-acting 2:1 ratio ABD-2 air booster.

The unit is mounted on a heavy-duty skid

with forklift provisions. It has receiver and regulator pressure gauges, a

safety relief valve, and drive controls. This is a low-cost solution for high

pressure and high-volume air applications.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 2:1 and

air drive pressure supplied is 150 psi, this means the output pressure is

approximately 300 psi.

1. ABD-2 ratio available: 2:1

2. Max air drive pressure: 150 psi

3. Max output pressure: 300 psi at 150 drive psi

4. Dimensions: 30” x 37.5” x 14”

5. Weight: approx. 145 lbs.

Modifications

One modification option is available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

11. ABD-5 Air Booster System

Similar to the ABD-2 Air Booster System but

lighter and more powerful. This system utilizes a 5:1 ratio, double-acting,

single-stage booster with a 600 psi ASME 5-gallon reservoir. It can be mounted

horizontally or vertically. It includes an inlet filter/regulator with shut-off

and gauge, muffler, safety relief valve, high pressure reservoir, outlet

pressure gauges, and high-pressure regulator. Good for pressures up to 600 psi.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The Air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 5:1 and

air drive pressure supplied is 50 psi, this means the output pressure is

approximately 250 psi.

1. ABD-5 ratio available: 5:1

2. Max air drive pressure: 150 psi

3. Max output pressure: 855 psi at 150 drive psi

4. Dimensions: 22.25” x 21.5” x 24.16”

5. Weight: approx. 85 lbs.

Modifications

Eight modification options are available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M205” – Cooling Jacket, Remote Pilot: air cooling system to lower

operating temperature in the high-pressure section.

“M200” – Refrigerant Recovery

“M201” - No Inlet / Outlet Plumbing

“M203” - No Inlet / Outlet Plumbing, Remote Pilot

“M204” - Cooling Jacket

“M206” - Cooling Jacket, No Inlet / Outlet Plumbing

“M207” - Cooling Jacket, No Inlet / Outlet Plumbing, Remote Pilot

12. SC Gas Boosters and Systems

GB Series Gas Booster Single Stage - Single Acting

12. SC Gas Boosters and Systems

SC Hydraulic differentiates itself from

competition with the speed to which it may custom build booster systems.

Standard lead time for systems are 1-2 weeks. This can be expedited for a fee.

Custom unit lead time typically runs 3-4 weeks which is less than half the time

of other manufacturers. Other manufacturers will quote 6-8 weeks for a standard

system.

How is SC so much faster? Other

manufacturers build many other systems. SC specializes in booster systems. They

are not a large rigid company, but a medium flexible one. They work closely

with each customer to satisfy their exact needs. In addition to this, SC

manufactures the parts used in their units on-site. They do not depend on

suppliers. Also, almost any booster they manufacture can be used in any system.

GB Series Gas Booster Single Stage - Single Acting

This series of gas boosters is SC’s

smallest design. Great for pressurizing small volumes or pressure testing small

components. The pressure chamber is hydrocarbon free. Can work with argon,

helium, nitrogen, oxygen, hydrogen, and pressure as low as 50 psi. Flow can

reach up to 14-SCFM.

Common applications:

General Information:

Air Drive

Require no electrical power. Powered by pressurized air. The air

drive psi supplied is translated to output.

(1) Coned and threaded high-pressure connection

for 1/4" O.D. tubing.

Refer to the corresponding gas booster performance

curve for operating pressures. Maximum material rated outlet pressures can be

reached under special operating conditions. Do not use air drive and/or gas

supply pressures that equate to higher outlet pressures than those

"maximum material rated outlet pressures" shown on the table. Refer to

Static Outlet Stall Pressure formula shown on a table (for example, for gas

booster model GBD-30 the formula is: Static Outlet Stall Pressure = 30*Pa+Ps).

Maximum recommended air drive operating pressure: 100-psi. Maximum rated air

drive pressure: 150-psi (only for static outlet stall pressure).

1. Lowest starting air drive pressure: 50 psi

2. Max air drive pressure: 150 psi (only for static outlet stall

pressure), otherwise 100 psi

3. Max output pressure: 11,250 psi

Modifications

Two modification options are available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M014” - Counter Port: Provides a 5/8-18-UNF thread port on the air

motor section. Can be used to install a mechanical cycle counter.

Service Options:

13. GB-D Series Gas Booster Single Stage - Single Acting

Double Head

Identical to the above GB series, but has a

double head that allows half the input pressure to achieve the same outlet

pressure as the GB series.

Common applications are consistent with the GB series. In addition,

the GB-D series is great for low flow, medium pressure applications. Nominal

pressure can reach up to 15,000 psi. The high-pressure section is oil-free.

Remote pilot control is possible with the modification.

Air Drive

Require no electrical power. Powered by pressurized air. The air

drive psi supplied is translated to output.

(1) Coned and threaded high-pressure connection for

1/4" O.D. tubing.

Refer to the corresponding gas booster performance

curve for operating pressures. Maximum material rated outlet pressures can be

reached under special operating conditions. Do not use air drive and/or gas

supply pressures that equate to higher outlet pressures than those

"maximum material rated outlet pressures" shown on the table. Refer to

Static Outlet Stall Pressure formula shown on the table (for example, for gas

booster model GBD-30 the formula is: Static Outlet Stall Pressure = 30*Pa+Ps).

Maximum recommended air drive operating pressure: 100-psi. Maximum rated air

drive pressure: 150-psi (only for static outlet stall pressure).

1. Maximum recommended air drive pressure: 100 psi

2. Max output pressure: 20,000 psi

3. Dimensions: 25.61” x 10.13” x 8.41”

Modifications

Two modification options are available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M014” - Counter Port: Provides a 5/8-18-UNF thread port on the air

motor section. Can be used to install a mechanical cycle counter.

Service Options:

14. GB Series and GB-D Series Double Acting Options:

Both of the above series have double acting

options: GBD series and GBD-D series.

GBD Series:

(1) Coned and threaded high-pressure connection

for 1/4" O.D. tubing.

Refer to corresponding gas booster performance

curve for operating pressures. Maximum material rated outlet pressures can be

reached under special operating conditions. Do not use air drive and/or gas

supply pressures that equate to higher outlet pressures than those

"maximum material rated outlet pressures" shown on table. Refer to

Static Outlet Stall Pressure formula shown on table (for example, for gas

booster model GBD-30 the formula is: Static Outlet Stall Pressure = 30*Pa+Ps).

Maximum recommended air drive operating pressure: 100-psi. Maximum rated air

drive pressure: 150-psi (only for static outlet stall pressure).

GBD-D Series:

(1) Coned and threaded high pressure connection

for 1/4" O.D. tubing.

Refer to corresponding gas booster performance

curve for operating pressures. Maximum material rated outlet pressures can be

reached under special operating conditions. Do not use air drive and/or gas

supply pressures that equate to higher outlet pressures than those

"maximum material rated outlet pressures" shown on table. Refer to

Static Outlet Stall Pressure formula shown on table (for example, for gas

booster model GBD-30 the formula is: Static Outlet Stall Pressure = 30*Pa+Ps).

Maximum recommended air drive operating pressure: 100-psi. Maximum rated air

drive pressure: 150-psi (only for static outlet stall pressure).

15. GBT Series Gas Booster Two Stage - Double Acting

This gas booster is two-stage, double-acting. Good for high flow,

medium pressure applications. Combining the first and second stages with a

hydraulic piston allows for higher compression ratios. Nominal pressure can

reach up to 12,500 psi. The high-pressure section is oil-free. Remote pilot

control is possible with the modification.

1. Maximum recommended air drive pressure: 100 psi

2. Max output pressure: 20,000 psi

3. Dimensions: 25.78” x 10.13” x 9.3”

Modifications

Two modification options are available.

“M202” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M014” - Counter Port: Provides a 5/8-18-UNF thread port on the air

motor section. Can be used to install a mechanical cycle counter.

Service Options:

16. SC Power

Units

30 Series Power Units

This series is the most compact and

lightweight of all 10 series pump power units offered by SC. Installation is

easy and everything is already mounted and connected on a base plate. Only air,

fluid supply, and work port connections are required to get the unit ready for

use.

There are two pressure ports on the unit.

One is an air exhaust muffler to reduce noise, and the other is a shut-off or

bleed valve. Furthermore, a liquid filled gauge made from stainless steel rated

for 30,000 psi is provided. More gauge options are available for higher

pressures.

Common applications:

Ordering Information:

First, choose the pump you need for your

application. Read our above section on 10

Series Pumps for a detailed comparison. Technical specs are provided for each

30 Series power unit below.

The 30-4 series uses a 10-4 pump, 30-5

series uses a 10-5 pump, and 30-6 series uses a 10-6 pump.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 30:1

and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 1,500 psi.

A. Starting air drive pressure: < 10 psi

B. Max air drive pressure: 100 psi

Buna-Nitrile and Viton seals are available for the air motor

section. Buna-Nitrile, EPR, and Fluorocarbon seals are available for the

hydraulic section. Special seals may be requested if needed.

Hydraulic section material can be constructed of aluminum bronze

& stainless-steel alloy, or stainless steel, or cad plated carbon steel,

stainless steel. Non-lubricated is standard, but lubricated is an option.

* Coned and threaded high pressure connection for

¼” O.D. tubing.

** Consult factory if gauge is desired.

Modifications:

Sixteen modification options are available.

"A" - "A" modification:

Provides dual seals in the hydraulic section with a bleed-off. This provides a

visual indication of seal leakage.

"B" - Bottom inlet (1): Provides

a bottom inlet connection for tank installation or alternate mounting.

"D" - Bottom inlet - heavy duty.

"E" - Bottom inlet -

"A" modification (1).

"G" - Isolator - heavy duty

(1,3).

"H" - Heavy duty (1): Provides

special packing in the hydraulic assembly for maximum performance where media

is contaminated. This will achieve higher life expectancy than standard o-ring

seals. “A” modification is included in “H” modification.

"J" - Bottom inlet -

"K" modification (1).

"K" - "K" modification

(1): Uses a special air piston in the

air motor assembly that lowers the stroke of the pump, reducing the

internal forces. This will increase motor life. Good for applications with

rapid pressure losses.

"M" - Bottom inlet -

"A" and "K" modification (1).

"N" - Isolator - "A"

modification (1).

"P" - Isolator - "K"

modification (1).

"Q" - Isolator - "A"

and "K" modification (1).

"R" - Isolator (1): Prevents the

hydraulic piston from retracting into the motor, preventing contamination. The

isolator is also a heat barrier.

"S" - Heavy duty - "K"

modification (1,3).

"U" - Heavy duty - bottom inlet -

"K" mod. (1,3).

"V" - Heavy duty - isolator -

"K" modification (1,30).

90 Series Portable Test Cart

The 90 series is a portable power unit. Works with all 10 series pumps and 100 psi air. Air drive controls, pressure gauges, valves, return line, pump hand attachment, and 5- or 10-gallon reservoir are included. Only two connections are required. Quiet operation with air exhaust muffler. Up to 65,000 psi.

S10011 L3 Tubular Power Units

90 Series Portable Test Cart

The 90 series is a portable power unit. Works with all 10 series pumps and 100 psi air. Air drive controls, pressure gauges, valves, return line, pump hand attachment, and 5- or 10-gallon reservoir are included. Only two connections are required. Quiet operation with air exhaust muffler. Up to 65,000 psi.

Common applications:

Ordering Information:

First, choose the pump you need for your

application. Read our above section on 10 Series Pumps for a detailed

comparison. Technical specs are provided for each 90 Series power unit below.

The 90-4 series uses a 10-4 pump the 90-5

uses a 10-5 pump and the 90-6 series uses a 10-6 pump. Next, choose the body

material, see below.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 10:1

and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 500 psi.

Buna-Nitrile and Viton seals are available for the air motor

section. Buna-Nitrile, EPR, and Fluorocarbon seals are available for the

hydraulic section. Special seals may be requested if needed.

Body Material

Hydraulic section material can be constructed of aluminum bronze

& stainless-steel alloy, or stainless steel, or cad plated carbon steel,

stainless steel. Non-lubricated is standard, but lubricated is an option.

** Consult factory if gauge is desired.

Modifications:

Eleven modification options are available.

"A" - "A" modification:

Provides dual seals in the hydraulic section with a bleed-off. This provides a

visual indication of seal leakage.

"B" - Bottom inlet (1): Provides

a bottom inlet connection for tank installation or alternate mounting.

"G" - Isolator - heavy duty

(1,3).

"H" - Heavy duty (1): Provides

special packing in the hydraulic assembly for maximum performance where media

is contaminated. This will achieve higher life expectancy than standard o-ring

seals. “A” modification is included in “H” modification.

"K" - "K" modification

(1): Uses a special air piston in the air motor assembly that lowers the stroke

of the pump, reducing the internal forces. This will increase motor life. Good

for applications with rapid pressure losses.

"N" - Isolator - "A"

modification (1).

"P" - Isolator - "K"

modification (1).

"Q" - Isolator - "A"

and "K" modification (1).

"R" - Isolator (1): Prevents the

hydraulic piston from retracting into the motor, preventing contamination. The

isolator is also a heat barrier.

"S" - Heavy duty - "K"

modification (1,3).

"V" - Heavy duty - isolator -

"K" modification (1,30).

L3 Series Power Units

These are very low volume, lightweight

power units. Read our section on L3 series pumps to

seeif these will work for you. If you find that the L3 pump will work for you,

you may integrate any of them with the below power units.

S10011 L3 Tubular Power Units

Weighs only 25 pounds, compact 18” wide x 19”

high x 15” deep design, and includes a 1- or 2.2-gallon reservoir with fill cap

and strainer. The reservoir is made of polyethylene to reduce the weight.

Compatible with all L3 series standard pumps and includes air controls,

shut-off, high-pressure gauge, manifold, bleed valve, and return line.

Common applications:

Ordering Information:

First, choose the pump you need for your

application. Read our above section on L3 Series Pumps

for a detailed comparison. Use the ordering table below to create your power

unit.

General Information:

Air Drive

Require no electrical power. Powered by pressurized air, nitrogen

vapor, or natural gas. The air drive psi supplied is translated to output

pressure using the pressure ratio. If the pressure ratio of the pump is 20:1

and air drive pressure supplied is 50 psi, this means the output pressure is

approximately 1,000 psi. A hand pump attachment option is available for precise

pressure control or great for applications where shop air is not available.

L3 & L3C ratios available: 20:1, 31:1, 40:1, 55:1, 79:1, 123:1,

133:1, 213:1

1. Starting air drive pressure: < 15 psi

2. Max air drive pressure: 125 psi (intermittent duty)

3. Max output pressure: 24,375 psi at 125 drive psi, 1.0 gpm flow rate

Operation

These pumps operate using the principle of differential areas. A

small diameter hydraulic plunger is driven by an air piston and provides a

pressure ratio that determines the maximum output pressure.

Cycle

When air is first supplied to the pump, the pump will cycle at

maximum speed with maximum flow. It will continue to cycle automatically as the

pressure increases. Only slight drops in outlet pressure or increase in air

drive pressure will occur each cycle, thanks to very low frictional resistance.

Equilibrium

When the air drive force and output pressure are equal, the pump

stops automatically. The pump will maintain pressure with zero energy

consumption.

Media

·

Plain water

·

All hydraulic fluids

·

Distilled and di-ionized water

·

Solvents

·

Mild chemicals

·

Liquified CO2

Features

·

316 Stainless Steel wetted

hydraulic construction

·

Lightweight (6 lbs)

·

3.5-inch x 7-inch body includes

inlet and exhaust muffler

·

Hand pump attachment option

Ordering Table:

Notes:

|

Additional Special

Modifications may be included with an "M" suffix at the end of the model number.

|

Modifications:

Seven modification options are available.

“M002” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M003” - SAE Straight Thread Ports: Provides SAE straight threads on

the fluid inlet and outlet ports

“M004” - Hand Pump Attachment: Provides a hand pump attachment great

for precise testing or an emergency backup for pneumatic power

“M005” - Distance Piece-Isolator: Provides

an isolator attachment that prevents the hydraulic piston from retracting into

the air drive, preventing contamination. The isolator is also a heat barrier.

“M006” - No Air Piston Return Spring: Provides improved fill in the

suction stroke when used with liquified gasses

“M008” - Noise Reduction: Provides a special, internal bumper

reducing noise without compromising power

“M009” – 7/16”-20 x 1/4" High-Pressure Fitting Outlet: Provides

a high-pressure fitting outlet

S10011

L3 Tank Mount Power Units

Perfect for

auxiliary hydraulic power for clamps, cylinders, etc. when volume is not a

factor. Weighs only 5 pounds, compact 18” wide x 19” high x 15” deep design,

and includes a 1-gallon reservoir. The reservoir is made of polyethylene to

reduce the weight. Compatible with all L3 series standard pumps and includes

air controls, high-pressure gauge, and return line.

Common applications:

Ordering

Information:

First

choose the pump you need for your application. Read our above

section on L3 Series Pumps for a detailed comparison. Use the ordering

table below to create your power unit.

General Information:

Air Drive

Require no electrical

power. Powered by pressurized air, nitrogen vapor, or natural gas. The air

drive psi supplied is translated to output pressure using the pressure ratio.

If the pressure ratio of the pump is 20:1 and air drive pressure supplied is 50

psi, this means the output pressure is approximately 1,000 psi. A hand pump

attachment option is available for precise pressure control or great for

applications where shop air is not available.

1. L3 & L3C ratios

available: 20:1, 31:1, 40:1, 55:1, 79:1, 123:1, 133:1, 213:1

2. Starting air drive

pressure: < 15 psi

3. Max air drive pressure:

125 psi (intermittent duty)

4. Max output pressure:

24,375 psi at 125 drive psi, 1.0 gpm flow rate

Operation

These pumps operate using

the principle of differential areas. A small diameter hydraulic plunger is

driven by an air piston and provides a pressure ratio that determines the

maximum output pressure.

Cycle

When air is first supplied

to the pump, the pump will cycle at maximum speed with maximum flow. It will

continue to cycle automatically as the pressure increases. Only slight drops in

outlet pressure or increase in air drive pressure will occur each cycle, thanks

to very low frictional resistance.

Equilibrium

When the air drive force

and output pressure are equal, the pump stops automatically. The pump will

maintain pressure with zero energy consumption.

Media

·

Plain water

·

All hydraulic fluids

·

Distilled and di-ionized water

·

Solvents

·

Mild chemicals

·

Liquified CO2

Features

·

316 Stainless Steel wetted hydraulic construction

·

Lightweight (6 lbs)

·

3.5-inch x 7-inch body includes inlet and exhaust muffler

·

Hand pump attachment option

Ordering

Table:

Modifications

Seven modification options are available.

“M002” - Remote Pilot: Provides a 1/8” NPT female port that can be

used to remotely start and stop the pump. This can be done by connecting an

external air signal to actuate the air cycling valve.

“M003” - SAE Straight Thread Ports: Provides SAE straight threads on

the fluid inlet and outlet ports

“M004” - Hand Pump Attachment: Provides a hand pump attachment great

for precise testing or an emergency backup for pneumatic power

“M005” - Distance Piece-Isolator: Provides

an isolator attachment that prevents the hydraulic piston from retracting into

the air drive, preventing contamination. The isolator is also a heat barrier.

“M006” - No Air Piston Return Spring: Provides improved fill in the

suction stroke when used with liquified gasses

“M008” - Noise Reduction: Provides a special, internal bumper

reducing noise without compromising power

“M009” – 7/16”-20 x 1/4" High-Pressure Fitting Outlet: Provides

a coned and threaded high-pressure connection for 20 KSI 1/4" O.D. tubing

(7/16-20 thread LF4 connection)

S10014 L3 Base Mount Power Units

“M002” - Remote Pilot: Provides a 1/8” NPT female port that can be used to remotely start and stop the pump. This can be done by connecting an external air signal to actuate the air cycling valve.

Source : https://www.gghyd.com/blog/sc-hydraulic-engineering/

S10014 L3 Base Mount Power Units

This is the most basic design for use with

L3 Series pumps. Weighs only 15-20 pounds, compact 9” wide x 10.5” high x 9”

deep design, and does not include a reservoir. Compatible with all L3 series

standard pumps and includes air controls, high-pressure gauge, pump, manifold

and bleed valve.

Common applications:

Ordering Information:

First

choose the pump you need for your application. Read our above

section on L3 Series Pumps for a detailed comparison. Use the ordering table

below to create your power unit.

General Information

Air Drive

Require no electrical

power. Powered by pressurized air, nitrogen vapor, or natural gas. The air

drive psi supplied is translated to output pressure using the pressure ratio.

If the pressure ratio of the pump is 20:1 and air drive pressure supplied is 50

psi, this means the output pressure is approximately 1,000 psi. A hand pump

attachment option is available for precise pressure control or great for

applications where shop air is not available.

1. L3 & L3C ratios

available: 20:1, 31:1, 40:1, 55:1, 79:1, 123:1, 133:1, 213:1

2. Starting air drive pressure: < 15 psi

3. Max air drive pressure: 125 psi (intermittent duty)

4. Max output pressure: 24,375 psi at 125 drive psi, 1.0 gpm flow rate

2. Starting air drive pressure: < 15 psi

3. Max air drive pressure: 125 psi (intermittent duty)

4. Max output pressure: 24,375 psi at 125 drive psi, 1.0 gpm flow rate

Operation

These pumps operate using

the principle of differential areas. A small diameter hydraulic plunger is

driven by an air piston and provides a pressure ratio that determines the

maximum output pressure.

Cycle

When air is first supplied

to the pump, the pump will cycle at maximum speed with maximum flow. It will

continue to cycle automatically as the pressure increases. Only slight drops in

outlet pressure or increase in air drive pressure will occur each cycle, thanks

to very low frictional resistance.

Equilibrium

When the air drive force

and output pressure are equal, the pump stops automatically. The pump will

maintain pressure with zero energy consumption.

Media

·

Plain water

·

All hydraulic fluids

·

Distilled and di-ionized water

·

Solvents

·

Mild chemicals

·

Liquified CO2

Features

·

316 Stainless Steel wetted hydraulic construction

·

Lightweight (6 lbs)

·

3.5-inch x 7-inch body includes inlet and exhaust muffler

·

Hand pump attachment option

Ordering

Table:

Modifications

Seven modification options

are available.

“M002” - Remote Pilot: Provides a 1/8” NPT female port that can be used to remotely start and stop the pump. This can be done by connecting an external air signal to actuate the air cycling valve.

“M003” - SAE Straight Thread Ports: Provides SAE straight threads on

the fluid inlet and outlet ports

“M004” - Hand Pump Attachment: Provides a hand pump attachment great

for precise testing or an emergency backup for pneumatic power

“M005” - Distance Piece-Isolator: Provides

an isolator attachment that prevents the hydraulic piston from retracting into

the air drive, preventing contamination. The isolator is also a heat

barrier.

barrier.

“M006” - No Air Piston Return Spring: Provides improved fill in the

suction stroke when used with liquified gasses

“M008” - Noise Reduction: Provides a special, internal bumper

reducing noise without compromising power

“M009” – 7/16”-20 x 1/4" High-Pressure Fitting Outlet: Provides

a coned and threaded high-pressure connection for 20 KSI 1/4" O.D. tubing

(7/16-20 thread LF4 connection)

Source : https://www.gghyd.com/blog/sc-hydraulic-engineering/